Trade Show Display Structures Review (cont’d) – Panel Displays

Continuing our review of trade show display structures, this post takes a look at panel displays. These have been around, and popular, for over 20 years. They are also called folding panel displays, flat panel displays, display boards, stackable panel displays, and trade show panel displays. The important word, and component, clearly, is a panel!

The panels used in panel displays started out made from plywood, but these days are primarily made from aluminum composites, dibond, or other composite materials, typically based on a very lightweight honeycomb interior of some sort, covered by two very thin, rigid aluminum sheets. These panels are finished with either a molded plastic frame, or an aluminum frame. The finish on the ends and sides can vary between manufacturers, with the inexpensive displays having exposed plastic or metal, and other designs electing to cover everything with fabric to provide a cleaner appearance.

On the outside faces, panels can be covered with a variety of  finishes – the most common for tradeshows is Velcro receptive fabric, but paint, printed graphics, 1,000s of different laminates, slat and grid wall, and a variety of other exterior surfaces are available. Often, a panel display will come with different finishes on front and back, either different colors of fabric on each side, or possibly fabric on one side and a graphic design on the other, or fabric and slat wall, etc. This offers two advantages; first, the display can be used with either side facing forward, providing two different looks, and second, it also allows the display panels to be used as a double-sided display.

finishes – the most common for tradeshows is Velcro receptive fabric, but paint, printed graphics, 1,000s of different laminates, slat and grid wall, and a variety of other exterior surfaces are available. Often, a panel display will come with different finishes on front and back, either different colors of fabric on each side, or possibly fabric on one side and a graphic design on the other, or fabric and slat wall, etc. This offers two advantages; first, the display can be used with either side facing forward, providing two different looks, and second, it also allows the display panels to be used as a double-sided display.

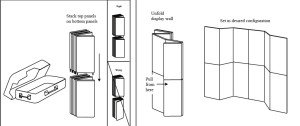

Panel sizes vary a little, depending on the manufacturer; typically they are about 2ft wide by 3ft tall. Single panels are often used as stand-alone signage, however trade show displays are most often made by combining panels into groups of 3, 4, 5, and 6 panels at a time. Panels are normally joined with a bendable hinge, and hinge construction is one of the differentiators between inexpensive panel displays, which may offer a simple cloth hinge, and the more expensive units, which may offer a 360 degree beveled gear hinge.

Trade show panel displays are typically used in a single row for table top displays, and stacked in two rows for floor standing displays. In most larger panel displays with two rows of panels, either row can be configured to work on a table top. The bottom row in a full size trade show panel display often has feet on it; some systems include an adjustment on the feet to compensate for uneven floors. The top row of panels uses pins sticking out the bottom of the panels that go into receiving holes on the top of the bottom row of panels, allowing the two rows of panels to stack on each other. Depending on the number of panels, the larger 5 or 6 panel strips usually need 2 people for setup and takedown.

Three and four panel configurations can be used to build towers and counters, as well as back walls. The five and six panel systems can easily fold panels back out of the way, if needed, to fit into smaller spaces, and these panel displays can also be combined to form larger, 20ft systems. As you might imagine for a 20 year old system, there are many different accessories available for trade show panel kits, including a variety of headers, lights, external and internal shelves, etc.

As with Pop Up Panel displays, there are a few derivatives of panel displays that have evolved over the years. One of these is the Pole Panel display system (pictured above). This uses a panel very similar to those used in standard panel displays, except these panels are typically slightly larger, and are used one at a time, and connect to each other by a fastener that hooks into a post or pole – hence the name, pole panel displays.

This arrangement offers a slightly different look, and the poles are available in different heights, allowing the panel displays to be raised or lowered, and allowing a single row of panels to be placed 3 feet off the floor, held up by the poles. Panels can also stacked two up, to create configurations similar

to the standard folding panel displays, but with a slightly different look. Pole panel systems are often seen at art shows, and also at toy shows and similar trade show venues. These systems are typically fairly heavy duty, and are suitable for high usage requirements and holding heavier display items.

Another display panel derivative, recently arrived from Europe, is the LITE panel system. The “LITETHING” is built with plastic based panels, slightly smaller in size, at 27” x 27” for the full size panels. The LITE panels are available in full size and half size, straight and curved shapes, and are connected with plastic nodes. The nodes can be flat or hinged, and there are even 3-way hinges.

The LITE panels are easily reconfigured into a variety of different shapes and configurations, by combining the different sizes and shapes and hinges in different ways. LITE configurations tend to be curved shapes and returns, allowing the panel displays to be stable without adding feet.

Graphics for the LITE panels come in two standard approaches; first is a laminated adhesive graphic very similar to that used for a vehicle wrap, adhered to the plastic face of the LITE panel. The graphic can be placed on front and back of the panels, allowing them to be turned around to show different graphics as required. Changing graphics requires removing the adhesive backed graphic, which means the old graphic skin will not be usable again.

The other graphic solution for LITE panels is a little bit more expensive up front, but makes a lot more sense if the graphics will be swapped frequently. This second approach places a magnetic underlay sheet on the LITE panel, and then printed magnetic graphic panels are produced. As one might imagine, these graphic panels can be swapped out almost instantaneously. Shelves, lights, monitor and iPad mounts, podiums and case wrapped graphics are available for the LITE panel displays.

The last panel display derivative to mention is the MultiQuad system. This system uses lightweight aluminum framing, in rectangular shapes of varying heights, to quickly assemble into 1ft or 2ft deep, box-like frames. Magnetic tape is used on the frames, and magnetic graphic panels quickly snap onto the MultiQuad displays.

The aluminum frames are lightweight, allowing for inexpensive shipping. However, the frames are fairly structural, and will easily provide support for large screen monitors, internal shadow boxes and shelving, etc.

Graphics are 23”x23” in front and back, 12” wide on the sides, and can be printed on translucent panels for backlit effects. The graphic panels are typically laminated to protect the graphic, and pack flat into a case or box for transport. Graphic panels can also accommodate almost any other finish available, including Velcro receptive fabric and 1,000’s of laminates. Exhibitors can reduce costs by skipping panels on the back side of their displays unless it will be exposed, and can also use the interior of the MultiQuad panels for easily accessible storage containers.

In summary, standard trade show display panels are a little bulkier to ship than pop up displays or the newer hybrid systems, primarily because the panels themselves are rigid and take up a fair amount of space – this normally means an extra shipping case, compared to a pop up or hybrid system.

However, folding panel displays are fairly thin, so they take up very little depth in a trade show booth. They also line up tightly, creating a crisp and professional looking trade show display. Using a fabric covered panel face means the graphics can be changed in a few seconds, even during a show. And of course, true tool-less setup means no expensive union help required…

The Pole Panel kits are about the same weight and take up the same number of shipping cases as a regular folding panel display, so the only real advantage besides the different look is the ability to raise the row several feet off the floor, using the poles as the support. If that is a requirement, maybe for an art show, then these are good solutions.

The LITE panels offer a very unique look – some love them, some don’t – and a 10ft display typically ships in one case that can convert to a podium. The MultiQuad system is similar in many ways to the LITE, except the LITE system will be based on curves, and the MultiQuad display will feature lots of straight lines and rectangles. Both are tool-less setups, both are smaller and lighter weight panels, and will help reduce shipping costs. Bottom line, as with many trade show display structures, a lot comes down to the eye of the beholder, and whether the viewer likes the look and feel of a particular system.

That’s it for trade show panel displays; please let me know if you think I overlooked any other panel systems, or any glaring advantages or disadvantages of the systems covered. Next post, we’ll take a look at modular and hybrid systems.