SEG Fabric Graphics

SEG Fabric Graphics – Intro

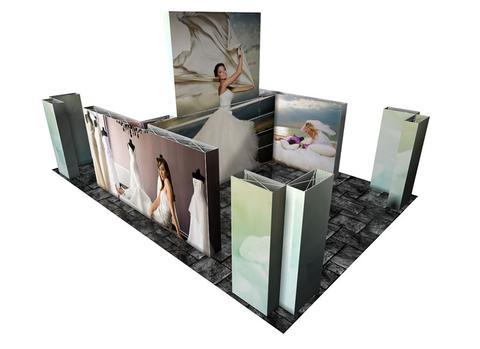

In this article we’re checking out one of a premium option for eye-catching trade show exhibits – SEG Graphic displays. SEG graphic displays are high-quality printed fabric graphics for crisp display purposes.

These displays come in various shapes and sizes, all with customizable designs. They have unique advantages over traditional graphics which pertain to quality, portability, cost-effectiveness, and more. We’ll examine SEG fabric in detail below.

What is an SEG Fabric Graphic?

Silicone Edge Graphics (often called SEGs) are a high-resolution dye-sublimated fabric graphic finished with a thin silicone strip. The silicone strip is sewn directly to the edge of the graphic, and the strip is then inserted into an aluminum frame with a recessed groove. The size of the silicone edge graphic must be precise so the fabric is taut when installed in the frame. The result is a large format graphic that mimics the old-fashioned traditional direct print graphics commonly found on custom displays and interior spaces.

Show labor costs are drastically decreased with silicone edge graphics. SEG graphics install quickly and easily-often by only one individual. Change-out can occur in minutes and take down is even quicker. The graphics fold easily for storage. Messages can be displayed on the same structure without taking up non-existent space. The result of the silicone edge graphics is striking. The fabric graphics mimic the old-time custom wall board or hard panel style graphics without all the hassle. Since SEG graphics are fabric, your booth will be glare-free and present a warm feeling with vivid color and deep presence.

Basically, these are custom, high-resolution graphics that are easy to set-up and easy to transport. You get a big, crisp display where you can proudly display your brand, your marketing message, or whatever you are looking to promote.

What are the benefits of Silicone Edge Graphics?

- Superior Fabric: The fabric is from only highest quality vendors

- Versatile: The SEG graphics can be used on many extrusion profiles

- Quality: The fabric undergoes a painstaking pre-inspection process before printing.

- High Resolution: SEG graphics are high resolution, for capturing even the smallest details in your image.

- Very Portable: The frames are interconnected, and can be disassembled after the show for easy transportation. The SEG fabric can be folded up, and you don’t need a lot of space to transport a high-quality graphic.

- Minimal Frame: The SEG allows for one of the slimmest frame reveals in the industry

- Seamless: Unlike other fabric graphics, the SEG sew line is hidden within the extrusion

- Can Be Backlit: Many SEG displays are available with backlighting for added attention to detail. The backlit SEG design provides a warm glow to draw more eyes to your display.

Displays with silicone edge graphics packages have significantly cheaper shipping costs and provide more room in the cases, making this easily one of the best looking and most convenient graphic styles.

SEGs, like other fabric graphics, have no glare from light, allowing for maximum graphic visibility from every angle. While fabric graphics are at risk for getting dirty or wrinkled, they are easily cared for with a washing machine or steamer at the show.

While SEGs also provide more graphic for your buck, the benefits extend beyond that: there is a growing list of fabric options for these displays that are created from mostly recycled materials, providing a greener option for exhibitors.

Customers of late have been relying on SEG graphics to display the most cutting edge, clean look in the industry while providing the user with a comfortable setup. The graphics are tight as a drum when installed, creating a vivid and seamless look from side to side. The corners are neatly finished with no bunching of the material; nearby there are concealed pull tabs to assist in removing the graphic.

While the SEG is easy to install, it's even easier to break it down by simply pulling the silicone out of the frame; it will fall out effortlessly and without stretching the graphic, but not so fast that it falls on the floor before you can catch up. There is improved storage, drayage, and shipping costs for fabric graphics.

What is a Tension Fabric Graphic?

Tension fabric graphics are the leading style in fabric graphics, allowing for the highest definition image to be printed on a fabric that becomes taut on your desired frame.

These graphicsy are installed "under tension", an engineering term that means they are stretched tight, which helps to eliminate wrinkles. These graphics are typically ready-to-use at all times and require little maintenance, especially from steamers (only required for improper and cramped storage situations).

Some of these graphics will install using an edge attachment such as SEG or Velcro system, and others simply wrap over framing system. Tension fabric graphics are the most popular form of graphics due to their storability, shipping weight, and reliability. Learn More

How do you install SEG?

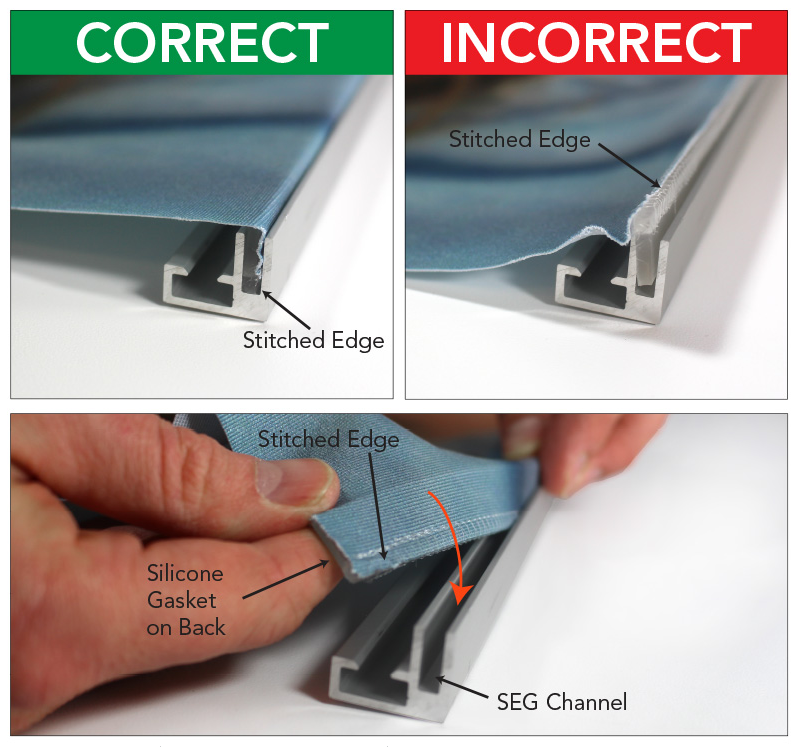

1. Fold Edge Once

One of the most common mistakes we witness with these types of graphics occurs when people apply the first, outermost edge into the metal frame instead of giving it one fold. The user must fold the silicone into the graphic once so that the sewn-edge is being applied first.

2. Pin all of the corners then halfway points

To properly apply the SEG, you must press the corners and midpoints into the seam - "pinning" them - before finishing the remaining loose edge. Make sure to avoid running your fingers along the silicone, chasing it into the seam. This may seem efficient, but it will cause damage to your silicone over time by stretching it to be longer, and your graphic won't be aligned properly.

Also, do not apply one length of side at a time; this also may seem to save time, but it will not guarantee proper alignment. The best practice is to pin all 4 corners, then to pin all 4 midpoints, then finish by pressing in the excess.

3. Finish applying all of the loose silicone into the seam

That's it. Press the remaining loose silicone into the seam in the extrusion and behold your stunning graphic.

It’s so easy to set up, and you can have a high-quality display in minutes!

SEG Fabric Ideas for Trade Shows

High-quality trade show accessories are great, but what’s more important is how you use those accessories. In this section, we’ll run through some tips for the best ways to use SEG fabric displays at your next trade show. Let’s start with the most important tip:

Use a Consistent Message: Passerbys at a trade show have between three and seven seconds to decide whether your booth is worth their attention. This means you need to make your message consistent. Decide on a simple message you want to communicate with your booth. An effective message should show a target group how your product or service benefits them. Make this message prominent and consistent throughout your booth, and this includes on your SEG fabric displays.

Strong Branding: Your booth displays should contain strong branding, and prominently display your brand name, logo, slogan, and however else you generally promote your brand. Some exhibitors display their branding several times throughout their booth, so it can be seen from all angles and from far distances.

SEG fabric graphics are ideal for this purpose. If you want to build awareness for your brand, sometime it’s best to keep it simple.

Display Product Images: Another popular way to use SEG graphics is to display high-quality product images. If you are primarily at the trade show to promote a specific product, then this is an effective use of your signage. Be sure that these photos are very high resolution and professional quality. An attractive photo of your product may be enough to communicate product benefits on its own.

Keep it Basic!: “Keep it simple” might be a cliché piece of advice, but clichés are popular for a reason. As mentioned, consumers have only seconds to decide on the worthiness of your booth. So whichever approach you decide on, be it promoting your brand or promoting an individual product or service, you need to keep your message simple and straightforward.

Decide on a benefit or marketing message you are trying to promote, and keep that consistent across your booth design, which includes your SEG fabric displays!

FAQs

What is the standard turnaround time for SEG?

Typical turnaround time is per customer request. Larger jobs require more production time and should be scheduled accordingly.

How are Silicone Edge Graphics shipped?

Some fabric choices will be shipped rolled onto a tube. It is important that any graphic initially shipped on a tube always be stored and shipped on a tube. Most SEG graphics will arrive folded and should be stored and shipped folded. Retain the plastic bag to keep your graphics clean.

What are the size limits of SEG?

- The maximum size (width without a seam) of a tension fabric graphic is about 118” (117” visual).

- Larger seamed graphics are available.

How does SEG fabric graphic quality compare to other materials?

All of our Tension Fabric Graphics are comparable in their stunning, high-quality resolution and clarity. Dye sublimation equipment is more advanced than ever offering near continuous tone (limited by the texture of the material you choose) and exceptional detail created from high DPI outputs and sophisticated image patterns. Color is permanently dyed into the fabric creating a deeply saturated image with vibrant colors.

How should you care for your fabric graphic?

It is recommended that silicone edge graphics be folded and stored in a bag. You may spot clean by wiping with a damp cloth. If it is necessary to wash the graphic and it is small enough, use a commercial size front-loading washing machine. Wash on the gentle cycle, with cool water. Dry cleaning is NOT recommended.

To limit getting the graphic dirty during installation, keep the set-up area clean by using a drop cloth and wash your hands prior to setup. You may want to consider purchasing inexpensive white cotton gloves. Wearing the gloves while handling the graphic will minimize the transfer of dirt and oils to your graphic.

Conclusion

Thanks for reading through our guide to SEG fabric graphic displays. We hope we’ve convinced you of the appeals of these high-quality graphics, and how they might benefit your next trade show. If you have any questions, or want to talk about your trade show needs, contact us today. We’d be happy to talk!